My ‘Smooth Sewing‘ trousers for the HSF ‘Innovations‘ challenge were made of rayon (as is the 1940s aloha shirt I paired them with), so it seems high time that I do a terminology post on rayon and the other ‘semi-synthetic’ or ‘manufactured natural’ fibres.

Rayon is the generic name for a whole family of fabrics made by dissolving cellulose fibres in chemicals and extruding the resulting viscous solution. Different chemicals and variations in the processes yield different types of fabrics in the rayon family. Viscose (called rayon in the US), cuprammonium (also known as cupra, cupro and Bemberg silk or Bemberg rayon), nitro silk, acetate, modal and lyocell are all types of rayon, as is most ‘bamboo’ fabric – which is simply rayon made from bamboo rather than other cellulose bases. Art silk (or artificial silk), is an older term for rayon, as is mother-in-law silk (which gives an indication about how people felt about rayon when it was first invented).

The first manufactured natural fibres have their origins in the exciting experimentation that characterised the birth of modern chemistry in the mid-19th century (a movement that also resulted in the first synthetic dyes).

Scientists discovered that cellulose could be dissolved in various solvents such as acetone and ether, and almost immediately hit upon the idea of creating a silk-like filament fibres from the resulting liquid. In the mid 1850s an otherwise little-known chemist named Georges Audemars created the first artificial silk fibres by dipping needles in cellulose dissolved in a solvent, and drawing the needles out to form a thin fibre. His method was obviously impractical for mass production. It took another half a century of tinkering to create a commercially viable manufactured cellulose based fabric.

His method, known as nitrocellulose, did go into production in the 1890s after further developments by Comte Hilaire de Chardonnet (mentioned in NZ papers in 1888) based on filament development for lightbulbs. Unfortunately the fabric was extremely flammable, had aesthetic issues, and was more expensive to produce than the other two competitors that had since arisen: acetate and cuprammonium. Despite these drawbacks, and despite being popularly dubbed ‘mother-in-law silk‘, nitrocellulose was manufactured throughout the first decade of the 20th century, until the disruptions of WWI ended its production.

By the early 1900s manufactured cellulose fabrics of various varieties were making headlines around the world. Articles raving about it had appeared as early as 1894, and by 1906 they reached a fever pitch with headlines like “The Wonder of Cellulose” and declared “Death of the Silkworm” and “Artificial Silk Can Be Made Cheaper Than Rags.” Viscose was sold in the UK from 1905, in the US from 1910, and in New Zealand from at least 1911.

World War I delayed the development of rayon and other cellulose based fabrics. When the war ended in 1918, society embraced new technology of all varieties as hallmarks of a new world which had been washed clean by the horrors of war, and could start fresh. Processed cellulose fabrics was one of these new technologies, and its popularity rose throughout the early 1920s.

Viscose in particular was originally marketed as a silk alternative – or artificial silk, shortened to art silk, to further veil its origins. Proponents raved that it was “so soft and glossy that it will deceive even experts when woven.” Less enthusiastic observers sneered that it was simply “disguised cotton” and noted “artificial the article certainly is, but silk it is not – any more than celluloid is marble.”

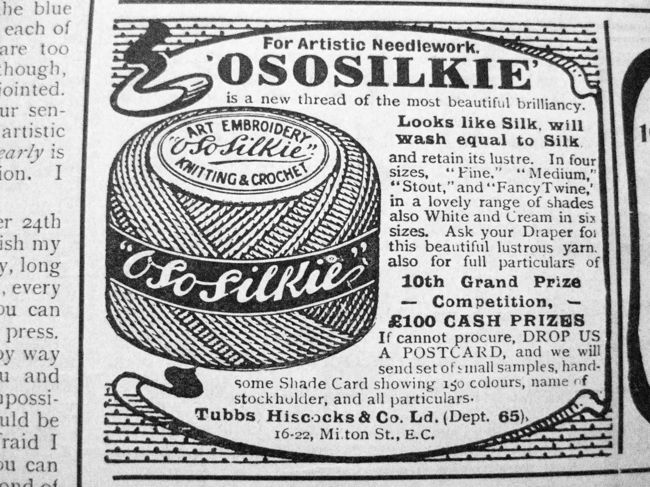

Despite the detractors, by 1925 rayon, with its ability to mimic both cotton and silk, combined with a significantly cheaper price tag, especially compared to silk, was being manufactured in large quantities in the UK, Germany and the US, and to smaller extents in Italy, Japan and other countries. Production of rayon in the UK almost quadrupled from 1924 to 1926. Silk remained pre-eminent for those who could afford it, but art silk was an attractive alternative to those on a budget. Art silk was manufactured as yarns for embroidery and knitting, as a flat fabric, as a crepe fabric, and as a velvet, among other types of fabric.

Rayon was also mixed with wool and cotton to create blends that were often cheaper than either of those fabrics in their pure form, or simply to create new and exciting fashion blends.

Sports dress that will be much in evidence this winter. The material is Cobra, one of the new rayon and cotton fabrics that will be made up into sports frocks as well as gowns for tea dansants and afternoon wear. Auckland Star, 11 April 1928

The popularity of art silk prompted chemists to try to devise a fibre that could mimic wool, resulting in the development of the short-lived and unfortunately named Sniafil. The fibres properties were apparently no more impressive than its name, and it is not mentioned again after 1927.

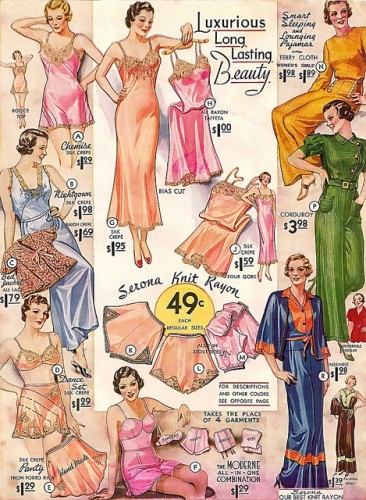

The entire manufactured cellulose fabrics industry became increasingly important with the economic crashes in 1929: more and more people could not afford real silk, and turned to art silk as a cheaper alternative. The first fashion illustrations for rayon frocks appear in NZ papers in 1927 (and these illustrations would have come from overseas, so reflect a clear global trend).

1930s rayon crepe Japanese import robe with rayon embroidery

The drawback to rayon was its quality: it crumpled more than natural fibres, and often did not last as well. Still, 1931 home economics textbooks advised that “with proper care and laundering, rayon may give as satisfactory wear as silk”. Early rayons were so weakened by water that even slight rubbing when washing could produce holes in the fabric. This weakness in water made rayon unsuitable for military use (can you just imagine how bad a parachute that weakened when wet would be?), so rayon filled the gap for a fashion fabric left by silk (which was in high demand for parachutes, and in short supply due to trade interruptions) during World War II.

In addition to an increase in demand for rayon, World War II also saw huge improvements in the qualities of rayon. Early rayons were (as mentioned) weak in water, couldn’t take hot ironing, and prone to creasing in wrinkling. Research into rayon technology spurred by a need for better, cheaper, fabrics during the war helped to improve the fabric, and also produced nylon, the first fully synthetic fabric.

Rayon has been continually improved since the end of WWII, based on fashion trends and cost demands. It’s now softer, stronger, more breathable, and easier to launder and care for. It’s also going through a bit of a resurgence as a fabric, motivated in part by rising costs in cotton caused by serious droughts in major cotton producing areas. Rayon, in all its forms, is easily found in off-the-rack garments and fabric stores – at least for now.

I’ve used art silk, rayon and viscose as synonyms up to this point, which is how they were used historically, but they aren’t quite synonyms today. So what is the difference between rayon and viscose?

Viscose was the trade name for the specific process developed by Charles Frederick Cross in 1894. It was used as the generic name for fabrics produced using variants of that process until 1924, when the holders of Cross’s patent petitioned in the US to have the name restricted to their process, and the actual viscous liquid, which could also be used to make cellophane. From 1924 viscose and other cellulose fabrics produced with similar processes were called by the generic name rayon, or art silk in the US, though they continued to be called viscose in Europe. Thus, modern equivalents of the fabric are called rayon in the US, and viscose in NZ/Australia/the UK today.

A smart three-piece sports ensemble of wool and rayon weave, featuring the popular jacket and set off by a large silk bandanna. Auckland Star, 25 June 1928

There was a time though, when the fabric was called rayon in New Zealand Advertisements for rayon, rather than viscose or art silk, first appear in New Zealand papers in March 1925. In the later half of the 1920s, and throughout the 1930s & 40s rayon was the most common term for manufactured cellulose fabric in New Zealand fashion articles and advertising. Only when rayon fell out of favour (replaced by the new fully synthetic fibres, like nylon) in the post war period did the name disappear. When rayon/viscose experienced a resurgence in the 1980s and new millennium, it was brought back to New Zealand under the name viscose.

Today rayon is the generic term for all of the manufactured naturals, while viscose implies a specific process and materials – so viscose is a rayon, but not all rayons are viscose. There are also:

– Acetate, acetate rayon, or cellulose is the second oldest manufactured cellulose fibre, with origins dating back to 1865, though it wasn’t until the turn of the century that a process that was commercially satisfactory was developed (interestingly enough, by the Dreyfuss brothers, who were also responsible for the first synthetic indigo dye). Acetate differs from viscose significantly in that in that acetate is hydrophobic (reacts very poorly to water and must be dry cleaned) and viscose is hydrophylic (loves water and absorbs lots of it). Acetate did poorly at first as a fashion fibre because the initial process was hard to dye (as it couldn’t be put in a dye bath) so was used primarily for industry. Acetate also reacts poorly to heat and melts easily – this does mean that it is one of the few semi-natural fibres that can be permanently pressed into pleats. Because of these drawbacks it wasn’t manufactured commercially on any great scale until at least 1924. Variants of acetate are Triacetate and Diacetate.

– Bamboo rayons (from bamboo fibres) – simply viscose or other manufactured naturals made with bamboo as their cellulose base. Bamboo can be processes into a fibre in two ways: mechanically, or using chemicals (as a rayon). The mechanical process is expensive and time and labour intensive, and results in a much stiffer, less attractive fabric. The rayon process produces a much nicer fibre, but is not particularly environmentally friendly. In some countries, such as the US, bamboo rayons must be marketed as such unless they are entirely mechanically processed. There are no such rules in New Zealand. It is possible to buy mechanically processed bamboo (it’s rather like a stiff, coarse linen), but its usually blended with other fibres to make it softer and more wearable. I’m reasonably certain that the stripes in my Subtly Striped petticoat are manufactured bamboo.

-Cuprammonium rayon is simply cellulose dissolved in a cuprammonium solution. Sold as cuprammonium, cupra, cupro, bemberg and bemberg silk, after the J.P. Bemberg company, who improved it and first produced in commercially in 1901. Cupro is usually a very light, fine, soft fabric, and is used as linings in quality suits and dresses, as it tends to last better than silk, but is nicer to feel and wear than acetate. It is apparently illegal to manufacture in the US at the present, due to the chemicals used to make it.

-I’ve been told by more than one American seamstress of my grandmothers generation that in the post WWII attempt to rebuild Japan’s economy fancy brocaded rayons were sold as ‘Kyoto silk‘. I’ve never found any marketing or research which definitively substantiates this, and Kyoto has always been famous for its gorgeous fabrics of real silk, so rebranding rayon as ‘Kyoto silk’ seems particularly unscrupulous on the part of marketers.

– Lyocell, trade named Tencel, is a relatively new rayon, only invented in the 1980s. Unlike most rayons it is strong when wet, and is highly absorbent. It can also be made to mimic a variety of other fibres and finishes, from suede to silk. It can be quite hard to dye, and has a tendency to pill, though both of these drawbacks can be overcome by additional processing. Lyocell is often marketed as the most environmentally friendly of the rayon processes, though some manufacturers use harsher chemicals to make the process faster and cheaper, as it is also the most expensive of the rayons to produce.

– Modal, is most similar to lyocell, and like lyocell is extremely soft and very absorbent. Along with lyocell it is currently being heavily marketed as a ‘green’ fabric.

Sources:

Cant, Jennifer and Fritz, Anne, Consumer Textiles. Melbourne: Oxford University Press. 1988

Garfield, Simon. Mauve: How One Man Invented a Colour that Changed the World. London: Faber and Faber Limited. 2000

Joyce A. Smith. Rayon — The Multi-Faceted Fiber. Ohio State University Rayon Fact Sheet

Rathbone, Lucy & Tarpley, Elizabeth, Fabrics and Dress. San Francisco: Houghton Mifflin Company. 1931

utsavfashion.comVery comprehensive. I recently noticed art silk the term is still used http://www.utsavfashion.com/saree/art-silk-fabric

My lovely new flowery pants from Shanton are made from 100% rayon according to the label. They fitted so nice, all loose and floaty. One wash and they are now are size smaller. No longer loose and floaty.

Wish I had remembered to buy a size bigger in case of shrinking.

The 3/4 pants from Just Jeans are 100% viscose and they havn’t shrunk. I have had trouble in the past but wasn’t sure which fabric was doing the shrinking. So now I am wondering have I been mixing up these two fabrics….does one shrink and not the other or is it just bad luck if it happens?

I must learn to read the labels and understand the fabrics so your post is helping.

The 100% rayon is probably a viscose rayon – some weaves of viscose rayon do shrink badly, so it’s really important that you follow the care labels and wash as directed! I generally wash my viscoses in cold water, but hand. Mildly annoying, but not as much as a shrunk garment!

ok , will be very careful to handwash in future. I put them in the washing machine but I did use cold water.

How fascinating! Thanks for the informative post Leimomi. I’ve always wondered what the precise differences were in all the semi-natural terms, but never did the research.

Thanks so much! If it is OK with you, I would love to use this information for my Fabric Technology classes. I try to explain but your explanation is so much more interesting 🙂

Regards, Polly

Thanks, and…erm, can you explain ‘use this information’ a little more? 🙂

Fascinating!

Fantastic, thank you so, so much!

I’m finding out I still don’t know what I’m dealing with. Acetate melts? In a burn test, too? I have these 15 meters of lining fabric that I thought were acetate… should I test it with water, perhaps?

This is fascinating!

I have a small box of very shiny embroidery thread with a label that reads “Artsyl Rope, Very Brilliant Artificial Silk for Embroidery, Manufactured by Belding – Corticelli Limited”. That box just got way more interesting.

I love these terminology posts!

The term ‘art silk’ is indeed still used here in India, I am not sure if it is rayon though. ‘Sand silk’ is used for polyester crepe & georgette in India also.

I bought some rather expensive Modal panties & a shirt in the US – I was assured by the salesperson that Modal was the latest luxury fabric. Unfortunately I found out that Modal ‘grows’ as you wear it resulting in the shirt turning into a tunic after 4 hours of wear & the panties went places you wouldn’t want them to go.

Eek!

Yes! And modal pills awfully as well.

It needn’t though – I own a couple of modal undershirts that are at least two years old, and well worn, with no pilling. It’s all about how they process it. And apparently improvement are being made all the time. Unfortunately I have no idea how one tells a modal that will pill from one that wont!

Thank you so much for this very helpful article! I am trying to source Cupro form UK and Europe and finding it nearly impossible to get my hands on. Could you suggest anywhere to search…?

Thanks again x

theliningcompany.co.ukLooks like The Lining Company has it:

http://www.theliningcompany.co.uk/catalog/index.php?cPath=32_77

would you please compare the various rayons in terms of creasing and stretching out of shape. Also do grease spots tend to stay?

Unfortunately that’s not possible. The creasing and stretching of each type will vary depending on weave, size of the fibre filaments, treatment during and after weaving, and the age of the fabric, as the technology has changed over time. I’d have to create a spreadsheet with hundreds of options. Grease spots will stay in manufactured naturals as they will in cotton.

Very helpful information, loved reading it, thank you! 🙂 I will be looking for more posts!

I play with yarn not fabric, but this article is super! Everything I ever wondered about the man-made ‘naturals’ has been clarified. Thank you very much.

Very informative! I do have a question: I have a shirt that is 52% Cupro Rayon, 44% Viscose, and 4% linen. Is it OK to hand wash this shirt in cold water?

It’s probably just fine, but you should follow the cleaning instructions that came with the shirt.

Queria saber se há alguma forma de tricotar e tingir malha para imitar cupro. E que fios devo usar.Se possÃvel enviar mail.

Obrigado

Cupramonium is a fibre, so it can’t be imitated by dye or knit 🙂

In tailoring books 1930s and 40s like the Modern Tailor, Outfitter and Clothier (Tailor & Cutter, UK) the sections on making always reference ‘art silk’ or ‘artificial silk’, never viscose.

Also Bemberg may be cuprammonium, but the current stuff sold under that name and Bemberg that was used some time ago is not identical. The latter has a very visible twilled weave and is noticeably thicker.

Much of the cloth identified as ‘art silk’ in vintage clothing is actually silesia.

I love some of the “new” fabrics that you have been talking bout so interestingly, but it seems to me that they are not that friendly since the process they use to make them uses solutions that sound rather nasty. I love your post thank-you.

So pleased you enjoyed the post! No, the processes aren’t that friendly, but unfortunately, the processes used to create 99.9% of cotton fabrics (even most organic cotton) and all full synthetic fabrics (polyester, nylon etc.) as well as most silks and linens are just as bad. They are all very heavy on chemicals, either as fertilisers for cotton, or dyes for all fabrics; or petroleum usage, in creating the fabrics themselves (synthetics) or weeding them (cotton, including organic), and wasteful of water. 🙁

My approach is to try to make clothes that wear really well, as the more times you can wear a garment, and the more gently you can launder it, the less its environmental impact per wear is. N